REPORTS

Our sustainability reports provide transparency and accountability on our environmental, social, and governance performance. They help us keep track of our sustainability goals and identify areas for improvement. In July 2023, the European Commission adopted the European Sustainability Reporting Standards (ESRS): The standards cover the full range of environmental, social, and governance issues, including climate change, biodiversity and human rights. These standards are not yet binding for the ZR Group, but we have nevertheless started working on a reporting structure based on their framework.

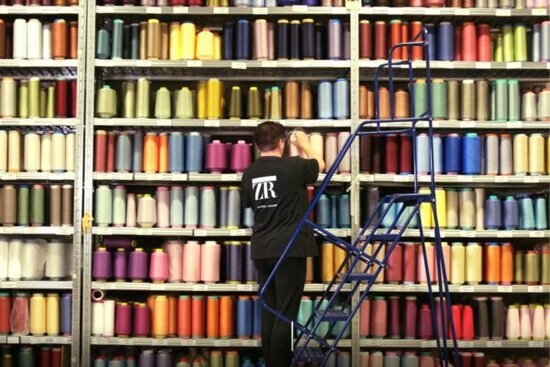

Zimmer + Rohde Group Sustainability Report 2023 > Download PDF